In today’s industrial landscape, automation represents a pivotal shift in how work is conducted. It offers significant improvements in efficiency, precision, and economic gains, yet it also fundamentally transforms the workforce by altering job roles and the essence of work. At the heart of this shift lies a crucial question: What impact does the rise of robots, AI, and automated systems have on occupational safety? This article explores the journey of occupational safety in the age of automation, examining how technology has reduced longstanding workplace risks while simultaneously presenting new challenges and opportunities for ensuring worker health and safety. We’ll look at various sectors, from manufacturing floors where robots operate next to human workers to office settings transformed by cognitive automation, to uncover how these advancements can steer us towards a future where work is both more productive and markedly safer.

The Industrial Revolution brought about transformative changes globally. While it introduced new risks through mechanization, it also eventually led to safer work environments. Factories, once dangerous, gradually became safer as awareness of the risks associated with heavy machinery grew, leading to better safety protocols. Occupational hazards in the United States, specifically transportation-related incidents, are still a major problem globally. This trend is also evident in Oregon.

There’s much room for improvement, especially in transportation, logging, and fishing industries which we will address in future articles. These sectors face persistent risks, but the promise of automation holds the potential to drastically reduce these occupational dangers. Automation has profoundly decreased transportation-related occupational fatalities by replacing human labor in dangerous tasks with technologies like Automated Guided Vehicles (AGVs) and robotics in warehousing and manufacturing, thereby reducing accidents from manual material handling. Additionally, automation has improved workplace safety by minimizing contact injuries, overexertion, and repetitive stress, while also shifting workers to safer, more strategic roles focused on overseeing and maintaining these systems, thus lessening their exposure to hazardous conditions.

This article explores the trajectory of occupational hazards, looking at both regional and nationwide trends over the last century. Although detailed data only became available from the early 1990s, more recent information offers clear insights into these patterns. We will specifically examine transportation-related fatalities and the impact of automation in this field. From the evolution towards fully self-driving vehicles to advancements in automotive safety features, as well as regulatory changes like mandatory rest periods for truck drivers, random drug testing, and speed limit modifications, we’ll assess how these elements contribute to enhancing transportation safety.

Transportation

Transportation-related deaths significantly influence the total number of occupational fatalities in Oregon. The strong correlation and significant regression coefficient indicate that fluctuations in transportation-related fatalities are a major factor in the overall trend of workplace deaths.

From 1992 to 2020, regulatory enhancements significantly reduced transportation-related occupational fatalities through mandatory seat belt laws, which saved thousands of lives; updated Hours of Service regulations by the FMCSA to curb driver fatigue with mandatory rest breaks and driving hour limits; and rigorous drug and alcohol testing programs enforced by OSHA and DOT to mitigate impaired driving risks, alongside technological improvements in vehicle safety.

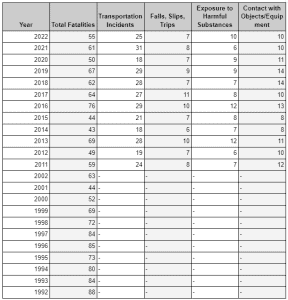

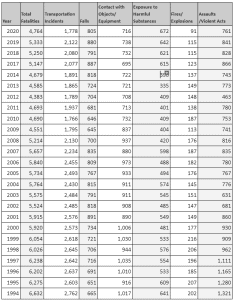

These tables summarize the key occupational hazards in Oregon and the US over the years, focusing on total fatalities and major incident types.

Outside of policy changes, transportation has been progressively automated for decades, often in ways we overlook. Consider airbags, an early form of automation introduced in the 1980s, which deploy autonomously to save lives by cushioning occupants during collisions. Anti-lock Braking Systems (ABS) from the 1990s automate braking to prevent skids, enhancing control in critical moments. By 2012, Electronic Stability Control (ESC) became another automated guardian, mandated to significantly cut down on single-vehicle crashes by maintaining vehicle stability. More recently, Advanced Driver-Assistance Systems (ADAS) have pushed the boundaries further, with features like automatic emergency braking and lane-keeping assist, actively intervening to prevent accidents. These technologies represent layers of automation that have quietly transformed vehicle safety, making our journeys safer through machines acting independently to protect us.

Automation has saved lives and will save even more in the years to come. Occupational deaths in transportation come in several forms: as a driver causing an accident, as a passenger, or as a driver or passenger in an accident caused by another vehicle.

Several companies are working on reducing the deaths by further automating the transportation industry. Most notably, Tesla has begun delivering its Semi trucks, with PepsiCo being a notable recipient, planning to expand its electric fleet significantly by incorporating 50 more Tesla Semis in California. Elon Musk has not recently provided updates on the exact production numbers or fleet size of the Tesla Semi, however past statements suggest the goal is to ramp up towards 50,000 in the next several years. This will significantly cut-down on the deaths related to driver fatigue and error both from the enhanced safety features and the full self-driving capabilities that will allow the vision enhanced software to make safety decisions when the driver or another vehicle is imperiled.

Tesla, Google’s (Alphabet) Waymo, and BMW are all also working to automate the passenger vehicle fleet which is already reducing the number of transportation deaths nationwide. Tesla claimed that a vehicle using Autopilot technology experienced one accident per 7.63 million miles driven, suggesting a safety rate significantly higher than the US average, which was more than 11 times less safe than a vehicle with these automation features. In 2023, Tesla mentioned that a Tesla with FSD Beta engaged experienced an airbag-deployed crash about every 3.2 million miles, which was claimed to be about 5 times safer than the most recently available US average, and it’s improving daily. This is reducing occupational hazards for both fleet vehicles that use Tesla’s and for every driver on the road that drives near a Tesla.

Waymo’s autonomous vehicles have demonstrated a significant safety advantage over human drivers, based on data from over 7.1 million driverless miles across Phoenix, Los Angeles, and San Francisco. Studies show that Waymo’s driverless cars were involved in 85% fewer injury-causing crashes and 57% fewer police-reported incidents than human benchmarks, highlighting an impressive reduction in both frequency and severity of accidents. This performance data not only underscores Waymo’s commitment to safety but also positions its technology as a potentially life-saving innovation in automotive safety.

Despite these advancements, Waymo’s journey hasn’t been without scrutiny. The National Highway Traffic Safety Administration (NHTSA) has initiated investigations following reports of unexpected behaviors in Waymo’s self-driving vehicles, indicating ongoing challenges in autonomous vehicle operation. However, even with these investigations, the overall narrative from Waymo’s operational data suggests that their vehicles significantly outperform human drivers in safety metrics, reducing both property damage claims and bodily injury claims dramatically when compared to human-driven vehicles.

BMW is actively advancing towards higher levels of vehicle automation, with significant developments aimed at introducing Level 3 autonomous driving technology. Collaborating with tech companies like Qualcomm and Arriver since late 2021, BMW plans to bring Level 3 capabilities to its models by the second half of 2025, focusing on the BMW 7 Series initially, with potential expansion to other models like Mini and Rolls-Royce. This technology allows for hands-off driving under specific conditions, utilizing Qualcomm’s Snapdragon Ride Vision system-on-chip and Arriver’s Computer Vision technology for enhanced autonomous functions. Furthermore, BMW’s partnership with Innoviz Technologies is set to enhance these capabilities through next-generation LiDAR, aiming for broader vehicle integration and the development of a Minimal Risk Maneuver system, which signifies a move towards more autonomous safety features and functionality in everyday driving scenarios.

On the manufacturing front, BMW’s commitment to automation is evident with its Shenyang factory, where 95% of the production line is automated, showcasing the integration of robotics for increased efficiency. Additionally, BMW has explored further automation with the introduction of autonomous robots in its Spartanburg plant, in collaboration with Figure, indicating a holistic approach to automation not just in driving but also in vehicle production. This reflects BMW’s broader strategy to blend driving pleasure with cutting-edge autonomous technology, making significant strides towards fully automated driving while enhancing production with AI and robotics.

As we’ve seen, the integration of automation into various industries not only streamlines operations but fundamentally enhances worker safety by reducing human error and exposure to hazardous conditions. From the factory floors to the highways, technology serves as both shield and sword in the ongoing battle against occupational hazards. Looking ahead, the journey of automation continues to unfold with promising prospects for even safer work environments. In our next article, we’ll delve into the logging industry, exploring how automation has not only made this historically dangerous job safer but also how it continues to evolve, setting new benchmarks for occupational safety in one of the world’s most challenging work environments.